In the realm of high-load systems, where performance and reliability are paramount, managing heat efficiently is a critical challenge. As electronic devices become more powerful, they generate significant amounts of heat that can degrade performance and reduce lifespan if not properly managed. One innovative solution to this problem is the use of tungsten copper heat sinks, which offer exceptional thermal management capabilities.

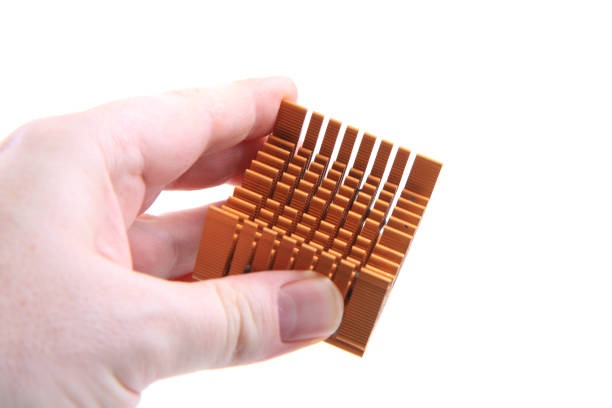

Tungsten copper composites are engineered materials combining the high thermal conductivity of copper with the low thermal expansion and high melting point of tungsten. This unique combination makes them particularly suitable for applications requiring efficient heat dissipation under extreme conditions. In high-load systems such as those found in aerospace, military, and advanced computing environments, these properties are invaluable.

The primary advantage of using tungsten copper heat sinks lies in their ability to maintain structural integrity while effectively dissipating heat. The high melting point of tungsten ensures that these heat sinks remain stable even at elevated temperatures typically encountered in demanding applications. Meanwhile, the excellent thermal conductivity of copper facilitates rapid transfer and dispersion of heat away from critical components.

Another key benefit is their adaptability to different design requirements. Tungsten copper composites can be precisely engineered to meet specific dimensional and performance https://amt-mat.com/understanding-tungsten-copper-heat-sinks/ criteria without sacrificing efficiency or durability. This flexibility allows designers to optimize the thermal management system according to unique operational needs while ensuring compatibility with existing hardware configurations.

Furthermore, tungsten copper’s resistance to corrosion adds an additional layer of reliability in environments where exposure to harsh chemicals or moisture might otherwise pose a risk. This characteristic extends the lifespan of both the cooling system and the protected components within it.

In addition to physical properties, economic considerations also play a role in selecting materials for thermal management solutions. While initially more expensive than some traditional alternatives like aluminum or pure copper heatsinks due primarily due its complex manufacturing process involving powder metallurgy techniques; however long-term benefits often outweigh upfront costs when factoring improved efficiency reduced maintenance downtime potential energy savings associated with optimized cooling strategies provided by superior material choice such as this one offers over lifecycle usage period making investment worthwhile decision overall especially mission-critical operations where failure simply cannot tolerated under any circumstances whatsoever given stakes involved at hand here today now moving forward future too!

Ultimately integrating into your next project whether starting anew upgrading existing infrastructure already place consider leveraging advantages offered through utilization cutting-edge technology embodied form modern-day marvel known affectionately industry insiders alike globally recognized leader field: Tungsten-Copper-based Heat Sinks! They represent pinnacle achievement human ingenuity engineering prowess combined together create truly remarkable products capable meeting exceeding expectations set forth ever-evolving world demands higher levels excellence each passing day moment time progresses onwards upwards toward brighter tomorrow filled promise potential awaits us all collectively united common goal success prosperity shared vision betterment humanity entire planet earth we call home cherish dearly hold close hearts minds souls forevermore eternal journey continues onward infinity beyond…